A crisis policy was adopted and is being implemented, which ensures the company's stable operation in conditions of the market headwinds and growth of the company's competitiveness.

There is a strengthening of positioning in the independent aftermarket, including through the development of the range for trucks and foreign cars.

The Certification Program for car service centers, retail and online stores was developed and implemented, allowing the Company to reach a qualitatively new level of product distribution.

The assortment of A-filters was expanded. By the middle of 2021 more than 70pcs of new items have been introduced, and its quantity is planned to reach 150pcs by the middle of the next year.

Spin-on oil filters were updated. First of all, the changes affected the most popular filters (GB-102, GB-102M, GB-107).

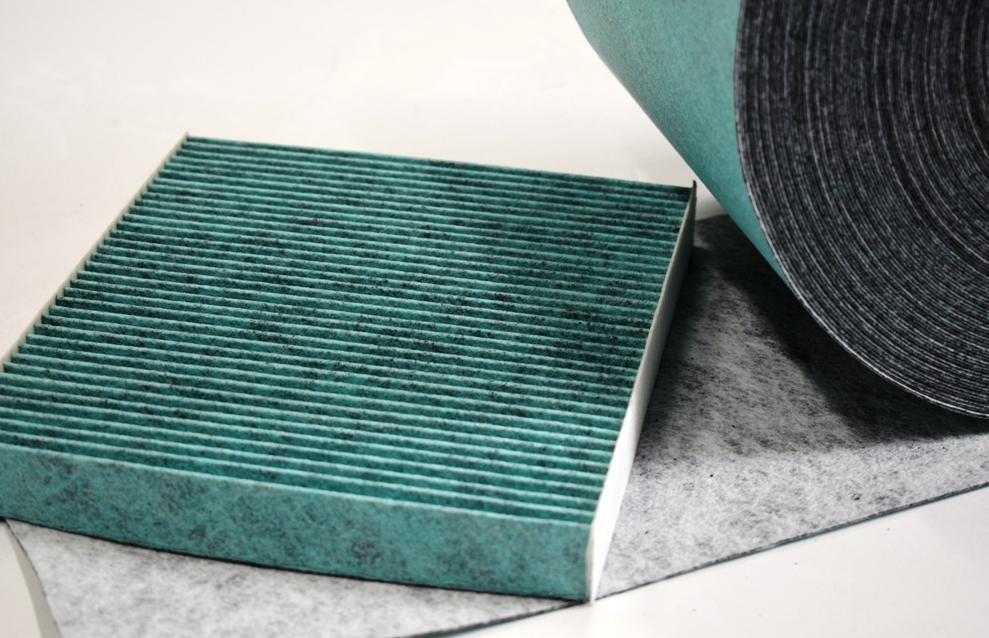

The delivery assortment of cabin filters, including A-filters to MOBIS - the official supplier of the original spare parts for KIA, HYUNDAI, was expanded.

The company has passed recertification audit for compliance with IATF 16949:2016 standard. As a result, BIG Filter confirmed its high status as a certified global OEM supplier for the next three years period.

The Company held the All-Russian Distributors Conference "Growing together - 2021. New Reality”. The conference was attended by over 60 representatives of BIG Filter distribution companies from different regions of Russia, including the largest wholesale and logistics companies of the country.

The regular annual supervision audit for compliance with the requirements of the international standard IATF 16949 has been successfully passed.

BIG FILTER's OEM range of products was expanded for AVTOVAZ and the PSA Peugeot Citroen warranty network.

Range of produced filters has been considerably expanded, including those for trucks.

A new pleating machine, made by JCEM (Switzerland), has been launched. It has greatly increased output of the line and quality of cabin filters.

A new equipment for infrared welding, made by GUSBI (Italy) has been installed, which allows the technology of welding filter curtain into plastic end disc.

A new thermoplastic automatic machine, made by ENGEL (Austria), with 160 ton clamping force, has been put into operation. It has enabled the Company to increase capacity for making parts by pressure die casting process.

Recurrent ISO/TS 16949, ISO 9001 certification has been well passed.

One more partner conference has been arranged, where BIG Filter presented aims of the Company till 2019 and strategy for their achievement.

By results of survey arranged by monthly business-edition AUTOINSTRUCTION in 2017 BIG Filter brand has entered the top 5 list of motor-car filter brands, represented in the Russian market, and re-confirmed the status of the strongest Russian filter brand.

Start of series supplies for PEUGEOT-CITROEN international concern.

Launched in operation:The Company traditionally represents the products on two sites of Automechanika, the leading international exhibition of auto component manufacturers, – in Moscow and in Frankfurt-am-Main.

The Company becomes a finalist in ‘Exporter of the Year’ annual competition for small and medium-sized enterprises, carried out by Saint-Petersburg government.

Victory in annual competition ‘Exporter of the Year’ in ‘Best Exporter of Automobile Components/Accessories’ nomination (organized by government of Saint-Petersburg).

VALEO audit passed with 87 points of 100. VALEO is one of the biggest OEM suppliers of the 1st level.

Further expansion of geography of supplies for European OEMs (total 9 automobile plants).

Start of cooperation with EMEX – All-Russian internet catalogue of automobile parts, containing above 70 million part numbers.

Expansion of geography of cooperation with VAG (Spain, Poland). Start of supplies by new air filter new project.

Full-scale reconstruction of production-warehouse complex completed.

Fiber-optic laser launched in operation. Modern technologies promote to higher level of manufacture and ecological requirements at production of fuel injection filters in stainless steel housing.

Hot Plate plastic welding machine launched in operation. It is now possible to produce more complicated units for main customers – global OEMs.

VW audit passed with 87 points of 100 (B rating). VW notes stable progress of the Company in quality and its compliance with European standards.

Quality Management System re-certified in compliance with ISO/TS 16949 requirements.

The Company celebrates the 25th anniversary.

Expansion of cooperation with AD RUSSIA Group of Companies (BERG, MIKADO).

New line for oil spin-on filter assembly launched in operation. The line is unique for Russia and is remarkable due to biggest output and high quality of curling.

Expansion of geography of cooperation with VAG: start of supplies for SKODA (Czech Republic).

Participation in development of air system concept for BENTLEY (UK). Getting invaluable experience in designing premium class items.

Victory in ‘AutoComponent of the Year’ competition in ‘Filters. Domestic brand’ nomination.

New nominations for supplies to VOLKSWAGEN Group conveyor. Expansion of geography of supplies for VW (Mexico).

Victory in ‘AutoComponent of the Year’ competition in ‘Filters. Domestic brand’ nomination.

Certification of quality management system compliance with ISO TS 16949:2009 and ISO 9001:2008 requirements.

New pleating line launched in operation, providing increased production capacities and considerable expansion of product range.

Nominations for supply of air filter to RENAULT-NISSAN conveyor and OES.

Start of filter supplies for biggest Russian internet shops of automobile parts: EXIST, AUTOPITER, AD FORTUNE WHEEL.

Start of serial supplies of filter in assembly to VOLKSWAGEN conveyor in Kaluga. BIG Filter – VAG supplier.

Victory in competition ‘Best Exporter of Saint-Petersburg’

New cabin filter line launched in operation.

Line for production of filters in assembly launched in operation. Road open for supplies of air filter modules to OEM conveyors.

Complete update and expansion of filter family, product range adapted to fit market demand for foreign car filters.

BIG FILTER products certified for VOLKSWAGEN and GME automobile plants.

Line for plastic filter component and filter element production retrofit. New equipment from Austria provides output increase of the retrofit line.

New line for production of air round and cylinder filters launched in operation.

New laser welding system for welding stainless steel fuel injection filters launched in operation, providing considerable increase in line output and keeping stable quality of welding seam at that.

New line for filter element production with new glue compound installed. The Company can now manufacture ecological filters.

BIG FILTER launches production of new generation ecological filters (fuel and oil), starting with fuel plastic filters.

Start of serial production of air panel filters on new imported technological line, operating in automatic mode by computer program; the line having no analogues in Russia.

Quality management system ISO 9001, implemented in BIG FILTER Company, is confirmed by international expert IQNet group and certified accordingly.

Expansion of automobile filter list, including new range of plastic fuel filters, for Japanese cars in particular, as well as oil filters.

The Company starts serial production of plastic filters for cars with fuel injection (injection filters).

First Russian catalogue of BIG FILTER products released.

Certification of quality management system compliance by international ISO 9002 standard.

Start of air round filter production.

Start of serial production of fuel plastic filters.

Company foundation in Saint-Petersburg, Russia.